Chapters 8.2

8.2 - Seed drying

Emily Overholt, University of Guelph, Canada

Suggested citation for this chapter.

Overholt,E. (2022) Seed drying. In Farmpedia, The Encyclopedia for Small Scale Farmers. Editor, M.N. Raizada, University of Guelph, Canada. http://www.farmpedia.org

Introduction

The Food and Agricultural Organization (FAO) of the United Nations estimates that post-harvest crop losses in sub-Saharan Africa amount to 8% of the total annual cereal yield (Kaminski & Christiaensen, 2014). These foods also provide nourishment to pests including fungi, insects, and rodents which lead to post-harvest losses (Kaminski & Christianensen, 2014). Seed drying is a vital skill for farmers to possess, as seed moisture content and incidence of infestation/disease are positively correlated (Bam et al., 2007). Wet grain leads to fungal molds and is more palatable to pests. The moisture content of the air, also known as the relative humidity, is a combination of the air’s temperature and moisture content (FAO, 2016). In order for seeds to lose moisture, they must have a higher moisture content than the air around them, which makes it especially difficult to dry grain in the humid tropics (FAO, 2016). Seed size/porosity and wind speed are also important factors in determining the drying capacity of a grain. The intent behind writing this paper is to provide subsistence farmers with a toolkit to evaluate different seed drying methods according to their specific needs and capacities.

Methods

This section will provide a brief overview of different indigenous practices. Indigenous populations have long understood the importance of seed drying for food security (Taruvinga, Mejia, & Alvarez, 2014). Whilst indigenous drying practices can be sufficient in providing some communities with year-round access to grain, population growth and climate change are undermining the viability of these systems within certain contexts (Mrema et al., 2011). Population growth lends itself to land scarcity, which can cause farmers to reduce crop rotations, given their finite resources (Mrema et al, 2011). What results from this reduction in biodiversity is an increased incidence of pests/fungi which often prefer specific host plants (Mrema et al, 2011). Equally important, the increase in average global temperature is conducive to fungi and pests (Taruvinga et al, 2014). Indigenous post-harvest drying methods can be grouped into four categories: field drying, open air drying, semi-open storage drying, and heated air drying (Taruvinga et al, 2014).

With respect to field drying, crops can remain in the field following grain maturation for up to 5 days, as a pre-harvest drying method (Taruvinga et al, 2014). Open air drying often consists of leaving grains on wooden structures where they are directly exposed to the sun and wind (Taruvinga et al, 2014); although, grains are also frequently hung from trees/poles. These methods are often used in very hot/humid environments, as well as with recently-harvested grain (Taruvinga et al, 2014).

The third method, semi-open storage drying, involves the construction of "cribs", which generally consist of a combination of timber, reeds, and bamboo (Taruvinga et al, 2014). The cribs are supported by a foundation of stone or wood with baffles, to protect grain from rodents (Taruvinga et al, 2014); ideally, the crib should be located at least 90 cm from the ground (Taruvinga et al, 2014). The semi-open method is employed to dry both threshed and unthreshed grain (Taruvinga et al, 2014); whilst unthreshed grain is limited in its drying capacity by the protective case which surrounds it, but is better fortified against potential predators (Taruvinga et al, 2014).

A fourth option for drying seeds is by means of heated air from fire (Sutherland & Ghaly, 1982). Whilst fuel may not be abundant, subsistence farmers can overcome this problem by placing grain in close proximity or above the cooking area. The heated air increases the relative air humidity, thus lowering the EMC (Mreme et al, 2011). It is important that heated air-dried seeds are stirred regularly, to avoid damage and/or under-dehydration of seeds (Taruvinga et al, 2014). Only after seeds reach an acceptable moisture content, can they be stored in bancos (Taruvinga et al, 2014). This indigenous concept involves crafting a container using mud or woven branches, bamboo, and grass as a method of insulating seeds from EMC (Taruvinga et al, 2014).

Practice

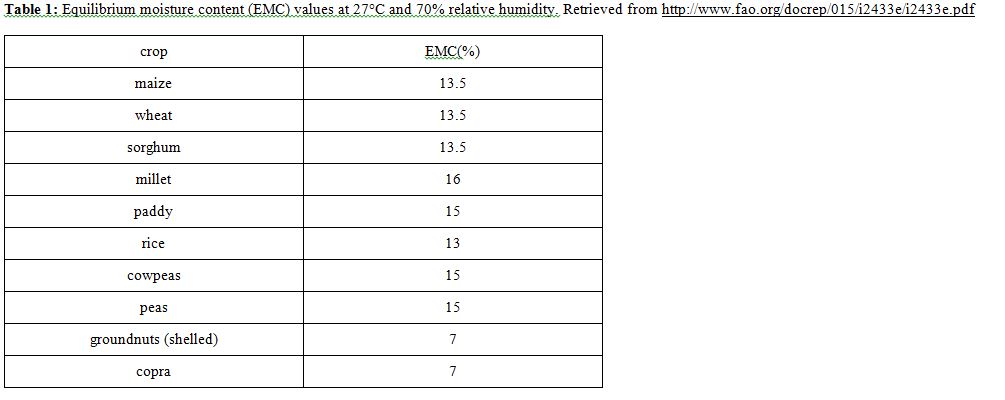

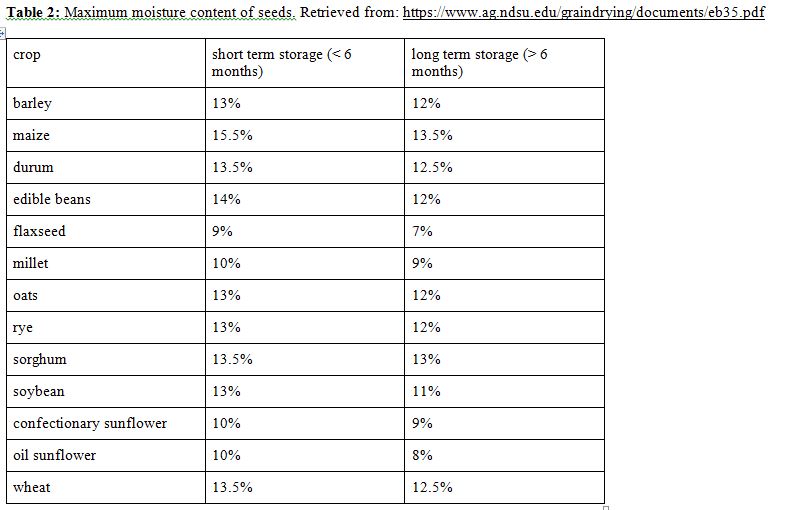

The optimal drying method and duration of a given grain is contingent on the climatic conditions, as well as the structure of the grain itself (Kozanoglu et al., 2012). It should be noted within the parameters of constant relative humidity that an increase of 10 °C in temperature will cause an approximate 0.5 °C decrease in EMC (Mrema et al, 2011); it has been theorized that this decrease in EMC is the result of increased water pressure within the seed, lending to higher moisture mobility (Barozzo, Mujumdar, & Freire, 2014). Being that grains differ in their EMC at a constant temperature/relative humidity, one cannot adopt a homogenous approach toward grain drying. As Table 1 shows, there is significant variation in EMC between crops when analyzed at 27 °C and 70% relative humidity (FAO, 2016). In fact, the EMC of groundnuts is half that of maize, despite being dried under the same climatic conditions (FAO, 2016). In addition to the discrepancies in drying capacity, seeds also vary in their optimal storage moisture content. Table 2 shows the maximum moisture content recommended by FAO for short and long term storage of different grains. Close examination of this chart shows that there is more variation between crops than between drying durations (Mrema et al, 2011).

Although porosity and seed size do not directly affect the EMC, they do have an impact on the rate of drying; through their effects on surface area and diffusion can catalyze the drying process, or cause a major lag in it, leaving the crops vulnerable to disease/infestation (Kozanoglu et al, 2012). Drying occurs on the grain surface and hence a greater seed surface to volume ratio results in faster drying of grain (Kozanoglu et al, 2012). Due to the large surface area ratio found in smaller cereal grains, the initial rate of drying is must faster than large grain (Kozanoglu et al, 2012). Although the larger grains are at an initial disadvantage, they typically surpass the drying rate of smaller seeds (Kozanoglu et al, 2012). This phenomena can be explained by the relatively high porosity found within larger seeds. Once an adequate amount of moisture has been depleted from seeds, pores catalyze the drying process, as they become conduits for airflow, and in doing so, increase the surface area to which air is exposed (Kozanoglu et al, 2012). Figure 1 shows a simple formula which farmers can use to determine moisture content of their dried grains, using only a scale and calculator. Once informed of their grain's moisture content, a farmer can begin to consider the different factors which influence drying technique and duration.

Application of drying methods

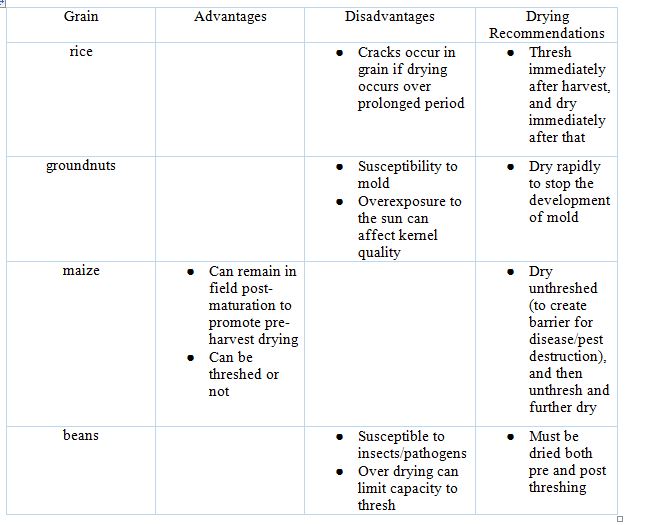

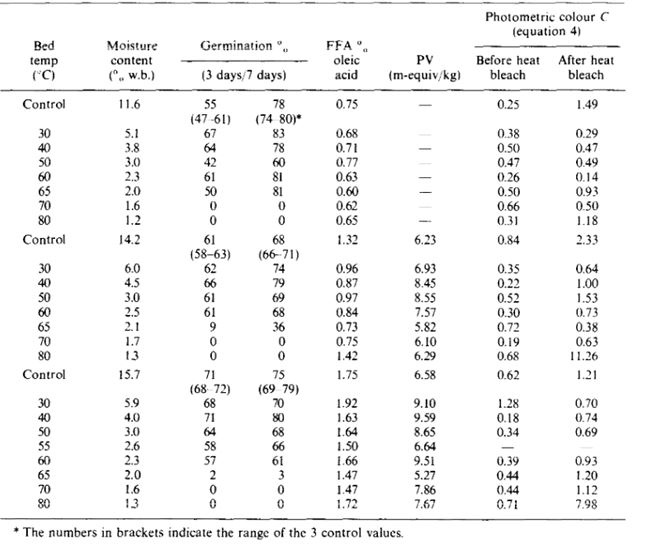

As crops differ in their chemical compositions, they also differ in their relative vulnerabilities to different threats. Table 3 summarizes the strengths and weaknesses of maize, beans, groundnuts, and rice; all of which are grown in Africa. Maize, for instance, is less likely to require heated-air drying than beans, based on its ability to dry in the field, as well as its superior resistance to insects and pathogens. Good management strategies should also consider the effects of different drying practices on the overall quality of the seed. Over drying and exposure to high temperatures can have an adverse impact on the quality of a seed, as well as its germination rate. Excessive temperatures can lead to an increase in internal air pressure of a seed, and lead to external damage (FAO, 2016). Furthermore, essential proteins, sugars, and glutens can be altered by extreme temperatures, leading to nutrient deficiencies in the seeds (FAO, 2016). The standard safe seed drying temperature for oilseed grains is 43 °C (FAO, 2016); although, Tables 4 and 5 exemplify the drastic variation in heat tolerance of different grains (Sutherland & Ghaly, 1982). Overheating can also affect flavor and color of the products which will reduce their market price (Sutherland & Ghaly, 1982).

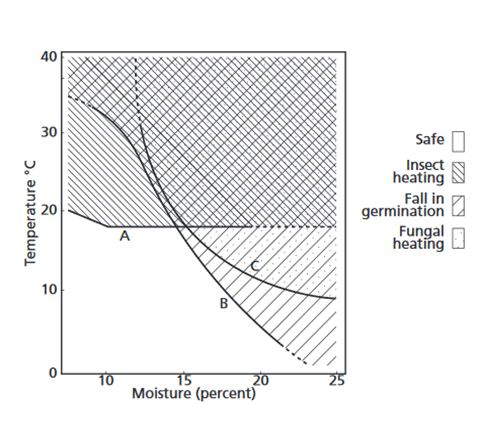

External factors that may influence the drying capacity of seeds, as well as their quality, include the cleanliness of seeds as well as the material on which they are dried. One study comparing the effectiveness of corrugated iron, cement, and wooden surfaces in promoting cowpea germination found that wood was superior for preventing pest infestation, and also had the highest rate of germination between the three (Ugwu et al., 1999). It has been suggested that the cleanliness of grain is an important determinant in the drying rate, given that these particles situate themselves within pores, and prevent full aeration (FAO, 2016). Rigorous cleaning should be undertaken in order to prevent this phenomenon, as well as reduce the risk of seed contamination (Kozanoglu et al, 2012). Caution should be taken during the cleaning process, as moisture-depleted seeds are more susceptible to compaction, which can limit porosity (Kozanoglu et al, 2012). Hopefully by now the reader has concluded that seed drying requires a complex management program as it is influenced by multiple factors. Figure 2 compares temperature with germination rate, insect activity, and fungal presence, in order to determine the safe drying temperature for most grain seeds (Mrema et al, 2011).

Critical evaluation

While heated air drying can have a critical impact on poverty reduction, it is important that farmers do not over rely on this method. Farmers may be incentivized to over-use heat drying, because it lends itself to quick drying, and therefore, readily available products to sell at market. While one could debate the finite nature of fuel resources, it can be said that population pressure will continue to increase demand for them, and lead to scarcity (as it already has in countries such as Ghana which suffer from significant deforestation). It is important to utilize other indigenous methods when possible, not only for their eco-benefits, but also to ensure their survival.

Effects of drying on profit/production

Different methods of seed drying can affect production through their labor and resource requirements. While in-field seed drying can increase available drying time, it also hinders the ability of farmers to engage in crop rotation, as growing seasons for staple crops are often finite (Taruvinga et al, 2014). Heat-drying seeds can be time consuming, as the temperature must be monitored and seeds must be constantly stirred. Semi-open grain storage can be labor intensive, as cribs must be built to house the grain. It seems reasonable to suggest that there is a positive correlation between initial seed moisture content and required labor inputs in the drying process. That being said, farmers choose to grow lower maintenance crops (in terms of drying) such as maize, rather than focus on growing the components of a balanced diet. Although there are no simple answers in the world of seed drying, one thing is certain: improved access to drying resources is a crucial component in bringing about food security. Seed drying allows farmers to maintain grain reserves throughout the year, which serves a two fold purpose: not only do farmers maintain a buffer against famine, they also receive a higher market value for grain during non-growing seasons.

Picture Based Lesson to Train Farmers

For the South Asian version (pictures only, text for you to insert), click this link for lesson 9.2:http://www.sakbooks.com/uploads/8/1/5/7/81574912/9.2_south_asian.pdf

For the East/South Asian version (pictures only, text for you to insert), click this link for lesson 9.2:http://www.sakbooks.com/uploads/8/1/5/7/81574912/9.2e.s.a.pdf

For the Sub-Saharan Africa/Caribbean version (pictures only, text for you to insert), click this link for lesson 9.2:http://www.sakbooks.com/uploads/8/1/5/7/81574912/9.2subsaharan_africa_carribean.pdf

For the Latin-America version (pictures only, text for you to insert), click this link for lesson 9.2:http://www.sakbooks.com/uploads/8/1/5/7/81574912/9.2latin_america.pdf

For North Africa And Middle East version (pictures only, text for you to insert), click this link for lesson Chapter 5. 8.2:http://www.sakbooks.com/uploads/8/1/5/7/81574912/8.2n._africa_middleeast.pdf

Source: MN Raizada and LJ Smith (2016) A Picture Book of Best Practices for Subsistence Farmers: eBook, University of Guelph Sustainable Agriculture Kit (SAK) Project, June 2016, Guelph, Canada. Available online at: www.SAKBooks.com

Additional resources

• http://www.fao.org/3/a-i3769e.pdf\

• http://www.fao.org/docrep/015/i2433e/i2433e10.pdf

• http://www.fao.org/docrep/T1838E/T1838E00.htmlhttps://www.fao.org/docrep/015/i2433/i/i2433e.pdf

• https://www.fao.org/docrep/015/i2433/i/i2433e.pdf

Appendix

M2 = 100 - [W1 (100 - M1)/W2]

W1 = weight of undried grain (kg)

W2 = weight of dried grain (kg)

M1 = moisture content of undried grain (%)

M2 = moisture content of dried grain (%)

Figure 1:

Equation for determining moisture content of dried seeds. Retrieved from: http://www.fao.org/docrep/015/i2433e/i2433e.pdfTable 3:

Recommended drying practices of different crops. Retrieved from:http://www.fao.org/docrep/015/i2433e/i2433e.pdfTable 4:

Impact of drying temperature on germination rates of sunflower seeds. Retrieved from:http://www.sciencedirect.com.subzero.lib.uoguelph.ca/science/article/pii/0022474X82900029Table 5: impact of drying temperature on germination rate of rapeseeds. Retrieved from: http://www.sciencedirect.com.subzero.lib.uoguelph.ca/science/article/pii/0022474X82900029

Figure 2:

Optimal seed drying conditions. Retrieved from: https://www.fao.org/docrep/015/i2433e/i2433e.pdfTable 6:

“Approximate” allowable storage time (days) for cereal grains. Replicated using information from https://www.ag.ndsu.edu/graindrying/documents/eb35.pdf*Approximate storage time exceeds 300 days. The columns are categorized according to storage temperature, and the rows according to moisture content of seeds after drying.

References

1. Bam, R. K., Craufurd, P. U., Dorward, P. T., Asiedu, E. A., Kumuga, F. K., & Ofori, K. (2007). Introducing improved cultivars: Understanding farmers seed drying and storage practices in Central Ghana. Expl Agric, 43, 301-317, doi :10.1017/S001447970700498X

2. Barozzo, M. A. S., Mujumdar, A., & Freire, J. T. (2014). Air-drying of seeds: A review. Drying Technology, 32, DOI: 10.1080/07373937.2014.915220

3. Hellevang, K. J. (1993). Natural air/low temperature crop drying. NDSU Extension Service.Retrieved from: https://www.ag.ndsu.edu/graindrying/documents/eb35.pdf

4. Kaminski, J. & Christiaensen. (2014). Post harvest loss in sub-Saharan Africa-what do farmers say? Global Food Security, 3, 149-158, DOI: 10.1016/j.gfs.2014.10.002

5. Kozanoglu, B., Martinez J., Alvarez, S., Guerrero-Beltrán, J. A., & Welti-Chanes, J. (2012) Influence of Particle Size on Vacuum–Fluidized Bed Drying. Drying Technology, 30 (2), 138 – 145, DOI:10.1080/07373937.2011.628427.

6. Mrema, G. C., Gumbe, L. O., Chepete, H. J., & Agullo, J. O. (2011). Rural Structures within the tropics: Design and development. FAO, Rome, Chapter 16. Retrieved from: http://www.fao.org/docrep/015/i2433e/i2433e10.pdf.

7. Proctor, D. L. (1994). Grain storage techniques: Evolution and trends in developing countries. FAO Rome, Chapter 5.Retrieved from: http://www.fao.org/docrep/T1838E/T1838E00.html

8. Sutherland, J. W. & Ghaly, T. F. (1982). Heated air drying of soil seeds. J Stored Prod Res, 18, 53-54.

9. Taruvinga, C., Mejia, D., & Alvarez, J. S. (2014). Appropriate seed and grain drying systems for small scale farmers. A Field Guide for Disaster Risk Reduction in Southern Africa: Key Practices for DRR Implementer, FAO. Retrieved from: http://www.fao.org/3/a-i3769e.pdf

10. Ugwu, F. M., Ekwu, F. C., & Abo, J. (1999). Effect of different sun-drying surfaces on the functional properties, cooking, and insect infestation of cowpea seeds. Bioresource Technology, 69, 87-90.